Desktop. Clean. Automated.

The G1/F1 brings the GENERA workflow and automation to your desktop. It is compatible with the GENERA validated material library and uses a cartridge-based material unit to store the materials. The G1/F1 utilizes the GENERA shuttle technology for a clean and safe workflow.

The F1 uses a flashlight for curing the parts in inert atmosphere.

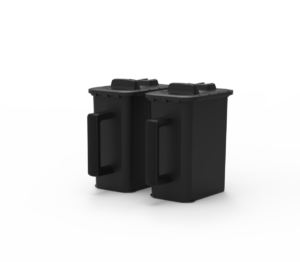

The parts are cleaned in two cleaning tanks especially designed for the secure use with IPA. The whole workflow is RF-ID tracked.

The material unit combined with a material cartridge ensures a clean and safe handling. The material unit is automatically opened by the G1 and the material is also automatically dispended. An integrated recoater helps to mix the resin within the resin vat to ensure consistent print results. The vat can be heated and track

low resin levels as well as the film lifetime. After the printing process the G1 automatically stores the part in the shuttle.

The part is then automatically post-processed by the F1.

G3

G3 A2

A2